FAQs

Some common questions regarding Industrial Hemp

A Broad Overview

The botanical name for industrial hemp is Cannabis sativa L (“sativa” means simply “that which is cultivated” and the “L” refers to Carl Linnaeus who gave this plant its scientific classification).

The cannabis plant has been used by humans for food, fibre, medicine and animal fodder for thousands of years. In the early part of the 19th century hemp was the world’s most widely cultivated crop when demand for sails, cordage and hemp textiles was widespread. The term “canvas” is derived from “cannabis”.

Different varieties of cannabis contain variable amounts of chemical compounds called cannabidiods. One of these compounds is tetrahydrocannabinol (THC) which can have psychoactive effects resulting in the ‘high’ commonly associated with marijuana. Another compound increasingly used for therapeutic purposes is cannabidiol (CBD).

Industrial hemp is defined as a plant that has been specifically bred to have LOW THC levels in the leaves and flowering heads so it has no drug value or effect and can be safely consumed as food. In Australia, industrial hemp is cannabis with less than 1% THC. In other regions like Europe and the USA, the limit is 0.3%.

Industrial hemp was spun into fibre over 10,000 years ago and today is grown for an expanding range of industrial and commercial uses. These include fabrics, clothing, ropes, shoes, food, paper, bioplastics, insulation, oils, cosmetics, dietary supplements, food products, animal bedding, garden mulch, etc.

The range and volume of these applications are expected to increase, thereby contributing to the growth of the global industrial hemp market while contributing to a sustainable and recyclable economy.

On 28 April 2017, the Australia New Zealand Ministerial Forum on Food Regulation (Forum) approved a proposal to amend the Australia New Zealand Food Standards Code to permit low-THC hemp seed to be sold as food.

Leaves, flowering heads and other parts of the low-THC hemp plant must NOT be sold as food for human consumption.

The changes to the Food Standards Code commenced on 11 November 2017.

Further information can be found on the Food Standards Australia New Zealand web page.

The United Nations conference (December 2022) on trade and development reports that hemp:

- requires significantly less water than growing cotton,

- absorbs more carbon dioxide per hectare than other crops and most trees,

- can grow in a wide variety of climates in most parts of the world,

- can be planted on land not suitable for other crops,

- helps to replenish the soil by removing heavy metals and other contaminants,

- is beneficial when included in crop rotation: eg hemp cultivation leads to a 10% to 20% increase in wheat yields,

- reduces waste as all parts of the plant – roots, flowers, fruit, stems and leaves – can be used. Other crops produce discarded parts which can have a huge ecological footprint. For example, in Africa, 80% or more of the cotton plant’s total mass is burned or discarded, contributing to heavy pollution. Similarly in India, burning harvest leftovers contribute to about half of Delhi’s deadly pollution, and

- has financial potential: the global market could hit $18.6 billion by 2027 – almost four times the amount in 2020.

Other sources note anti-microbial properties, resistance to UV, mould, mildew and rot. It can also be beneficial in terms of biodiversity as bees love it.

The plant consists of flower, seed, stalk, leaves and a tap root.

The flowers, seed and roots can be used for food, flour, oils, and extracts.

The stem of the hemp plant is made up of two components:

- the outer bark, or ‘bast’, which contains the long fibres used for textiles, rope, packaging, paper and food fibre, and

- the inner ‘hurd’, (the woody core of the plant with much shorter fibres) used in building products, insulation, biofuels and mulch.

About 40 countries produced some 275,000 tonnes of raw or semi-processed industrial hemp in 2019, according to the latest available statistics. But just four countries account for more than half of global output. China grows the most, followed by France, Canada and the United States.

China intends to plant 3.2 million hectares of hemp fiber by 2030 with the aim of replacing cotton with a more sustainable alternative for textiles.

Hemp cultivation in Australia peaked at 2,500ha in 2021 with more than half grown in Tasmania. An oversupply of hemp seed and competition from imported products especially from China led to a subsequent reduction in hectares under cultivation.

With a growing interest and investment in processing for fibre and hurd hemp cultivation is expected to increase significantly in coming years.

Growing and Seed Supply

Industrial hemp plants grow well on fertile, neutral-to-slightly alkaline, well-drained clay loam or silt loam soil types.

Hemp is a warm weather crop, and seed will not germinate well if the soil is too cool. Optimum soil temperature for seed germination and emergence is above 20°C. Provided with favourable conditions, hemp seeds germinate within 24 to 48 hours and can emerge to become seedlings in 5 to 7 days.

Optimum growth occurs when temperatures are between 25°C and 30°C. Hemp grows best with good levels of nitrogen especially when it is young and actively growing.

Commercial soil tests are recommended to determine availability of the major nutrients, nitrogen, phosphorous and potassium, the micronutrients such as trace elements, soil acidity (pH) and buffering capacity.

Whilst hemp requires less water than many crops, irrigation is highly recommended to ensure yield potential. Growers may choose to install soil moisture meters to monitor soil dryness.

A wide selection of hemp varieties are now available to suit conditions in diverse locations around the world. The choice of the grower will depend on the target market whether for fibre, food or therapeutic extracts.

Usually a grower will decide on either a fibre crop or a hemp seed crop, although dual crops are also possible.

Growers targeting fibre production (meaning any use of the stalk), will want to produce tall plants with less energy devoted to seed head or flower development.

Where hurd is the desired product, e.g. for hempcrete, growers will choose varieties and a planting density that encourages the development of thick stems for maximum yield of the woody core.

To produce bast fibre for textile production growers will choose varieties and a planting density that encourages the development of thin, tall plants to maximize yield of the outer skin of the stalk.

Edible seeds crops, or where the leaves and flowers are being harvested, require a different ratio of male to female plants and a wider, shorter plant.

An Australia-wide 3-year long trial of multiple varieties is currently underway to test the best variety for different purposes and conditions.

Seed for sowing must be certified and will typically produce hemp plants with a concentration of THC in leaves and flowering heads of not more than .05%.

The legal limit for industrial hemp in Australia is 1% THC.

Australia participates with over 50 other countries in the Organisation for Economic Cooperation and Development (OECD) Seed Schemes for the Varietal Certification of Seed Moving in International Trade.

This provides technical standards and procedures for the production, processing and labelling of Certified Seed.

A list of suppliers can be found on our Seed Supplies page.

Check with your state regulatory body for import requirements if you plan to obtain seed from interstate or overseas.

Licensing – make sure you are familiar with the legislation and regulations in your state and obtain all relevant licenses.

Research – get timely advice from an experienced agronomic consultant to help you plan the most suitable crop for your location and market conditions. Seek validation by experts.

Business Plan – Create a 3 – 5 year plan to ensure a viable investment, noting that with experience you can expect to get improved yields and quality.

Equipment – Ensure you have access to the necessary equipment for cultivation, sowing, irrigation and harvesting. Seed will need to be dried within 24 hours of harvest before being cleaned and stored for processing.

Be prepared to meet all testing requirements as the crop matures.

Licensing and Testing

Each state and territory in Australia has its own legislation and regulations pertaining the cultivation, processing and storage of industrial hemp.

They typically cover different aspects of the process such as growing, processing and supply as well as research.

Licence applicants are required to provide national police history checks and site inspections are generally required.

Licences are issued for up to 5 years with application and inspection fees varying from state to state. Click here for a summary of the legislation and regulations of each state and territory.

Every industrial hemp crop grown must be tested for levels of THC at the expense of the grower. Usually one or two samples will be collected for each crop sown.

This is required as evidence that the industrial hemp crop is being produced with THC levels below limit 1% at harvest.

Agronomic factors such as soil type, nutrition, sunlight hours and moisture can all influence THC levels and result in levels rising above 1% unintentionally.

In Tasmania, the Department of Natural Resources and Environment requires that licencees provide secure storage and transport to protect against spillage or theft of plant material.

Harvest, Processing and Manufacture

If a crop is harvested for seed, a combine harvester is used. This lifts and cuts the crop just below the seed head, which is typically the top one-third of the plant. The seed is collected and all other material is left on the ground in the paddock. This leftover product may be baled to create secondary products.

If grown for fibre, the industrial hemp crop it is harvested with a winnrower which lays it down in a row. The fibres are then broken down by raking and retting. (Retting is a process using bacteria and moisture to dissolve or rot away much of the cellular tissues and gummy substances surrounding bast-fibre bundles, thus facilitating separation of the fibre from the stem.) Then it is typically baled and taken to a processing plant

The female plants are closely watched until:

- 75% of all seed heads (buds) are green while few leaves on the seed heads have become relatively brown;

• The seeds at the base of the stem are turning grey;

• The stem fibres have shed most of their leaves, but are not completely mature.

Hemp seeds can be sterilised, dehulled, and packaged for food. Hemp seeds have a nutty flavour and can be sprinkled on salads, cereal or used in cooking.

High quality hemp seed oil, high in nutrition and similar to fish oil, is made through cold pressing.

Heat treatment can produce a ‘Refined Hemp Seed Oil’ which, though a lower quality oil, offers a wide range of commercial applications.

The seeds can also be used in the manufacture of commercial paints, oils, lubricants, varnishes, and even Biodiesel.

The stalk or stem of the plant is harvested for the outer layer “bast” or the inner layer “hurd”.

Bast (or hemp fibre) is generally used for textile, rope, canvas, insulation, bioplastic or biofuel.

Hurd is used for manufacturing the building material hempcrete, for acoustic surfaces, insulation, hemp pellets for heating and animal bedding.

Hurd (the fibrous interior of the stem) is usually harvested at the point that the last pollen is shed, which is about four months after sowing the seeds. The hemp stalk gets broken into small fragments, and the Hurd is separated from the fibres and impurities are removed through a process called scutching.

In the first five years of production, Tasmania produced close to 80% of all hemp grown in Australia. Our state experienced year-on-year growth in planting area to a peak in 2021 where there was 1,400ha under cultivation. At the time, this accounted for more than half of the 2,500ha grown that season across Australia.

In the following two seasons, a There is just one hemp fibre processing mill in Tasmania, X-Hemp, which converts the grain stubble left from the hemp seed harvest (which was previously burned or ploughed back into the paddock as waste) into products such as hempcrete which is a beautiful and insulating building product. X-Hemp was a THA sponsored initiative and is one of the small handful of hemp fibre processing facilities in the country.

Learn More

You can find the membership details for your state here.

The Australian Hemp Council brings growers, processors and industry supporters from around the country. It promotes research and industry development and is actively involved in advocating for a reduction in the regulatory burden affecting the hemp industry.

Members of the State Associations which comprise the Australian Hemp Council have complementary access the the AHC Growers Forum.

Attend the Australian Industrial Hemp Conference 2024

Subscribe to the AHC Newsletter

Subscribe to free newsletters from your state association

Subscribe to HempToday eNews

The Emperor Wears No Clothes – By Jack Herer

ISBN 978-1878125002

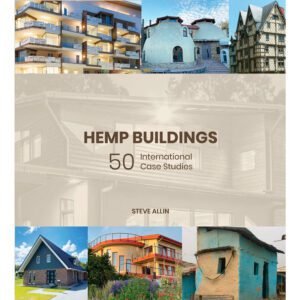

Hemp Buildings – 50 International Case Studies – By Steve Allin

ISBN 978-0-9551109-7-9

Building with Hemp. SeedPress – By Steve Allin (2005)

ISBN 978-0-9551109-0-0.

Building with Hemp 2nd Edition. SeedPress – By Steve Allin (2012)

ISBN 978-0-9551109-1-7.

Hemp Can’t Save The Planet BUT It Might Save Humanity! – By Steve Allin (2016).

ISBN 978-0-9551109-6-2.

The Hempcrete Book: Designing and Building with Hemp-Lime – By William Stanwix and Alex Sparrow

ISBN-13 978-0857841209

We are grateful to the

We are grateful to the

The AIHC was conceived and designed by its founder, Robert Bell, to both add value and to assist in the future expansion of the industrial hemp industry and its community.

The AIHC was conceived and designed by its founder, Robert Bell, to both add value and to assist in the future expansion of the industrial hemp industry and its community.

Health

Health

Our Top 5 Cultivars have been developed without genetic modification to grow and thrive in most regions of Australia.

Our Top 5 Cultivars have been developed without genetic modification to grow and thrive in most regions of Australia.

AVAILABLE PLANTING SEED:

AVAILABLE PLANTING SEED:

As the Deputy CEO of the Northern Territory Farmers Association (NT Farmers), I am committed to advancing agricultural development in Northern Australia.

As the Deputy CEO of the Northern Territory Farmers Association (NT Farmers), I am committed to advancing agricultural development in Northern Australia.  Jaimie Milling is a fourth-generation farmer who has been in the agriculture industry all his life.

Jaimie Milling is a fourth-generation farmer who has been in the agriculture industry all his life.